Introduction to the characteristics of SNCR denitration spray gun

1. Material of SNCR denitration spray gun:

Due to the high working environment temperature of the SNCR denitration spray gun, its use temperature is generally (850 degrees -1100 degrees). In the SNCR denitration system, the flow rate of the flue gas in the boiler or pipeline is fast, and the flue gas is mixed with a large amount of dust. In harsh environments, the denitrification spray gun wears severely. The material of the denitration spray gun must be high temperature resistance, corrosion resistance, and wear resistance; the spray gun rod of the denitration spray gun is required to be made of 310SS or higher, which can maintain high strength, corrosion resistance and good wear resistance in an environment below 1200 degrees , Ensure the continuous balance of denitration.

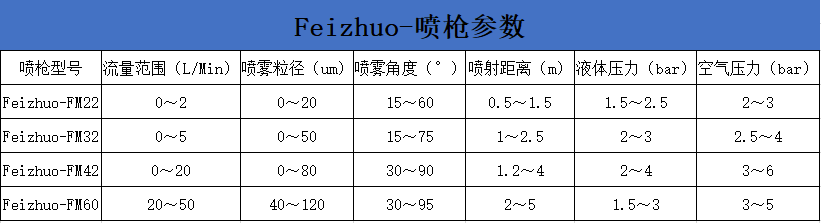

2 The atomization effect of the denitration spray gun and the uniformity of the flue gas mixing

The spray angle of the SNCR denitration spray gun ranges from 15 degrees to 150 degrees, and the penetration power of the liquid is different for different spray angles. A small angle denitration spray gun has strong spray penetration, and a large angle denitration spray gun covers a large area. The length of the denitration spray gun and the spray point into the furnace are different. Use a variety of different angles of denitrification spray guns, the installation position through CFD flow field simulation analysis combined with on-site measurement to obtain a good layout, so as to achieve a higher denitration efficiency.

3. The scalability of the denitration spray gun

SNCR denitration spray gun generally comes with a retractable adjustment function. In one case, when there is a small amount of deviation between the site working conditions and the design, the position of the denitration spray gun can be flexibly adjusted to ensure good denitration efficiency. In addition, when the denitration spray gun is not in use, it can be withdrawn from the furnace at any time, thereby prolonging the service life of the denitration spray gun.

4. Atomized particle size of denitration spray gun

The atomized particles of the SNCR denitration spray gun do not need to be cooled like the flue gas. The finer the better, the moderate flue gas particles can achieve good denitrification efficiency. The particles are too small and the penetration is poor, which reduces the denitration efficiency; the particles are too coarse and the particles are discharged The distribution area is reduced and the denitrification efficiency is reduced. At the same time, due to the fast flue gas flow rate, the spray particles cannot be completely atomized in a short time, and the generated droplets will cause the furnace to burst. Therefore, the atomized particle size should be selected according to the specific situation.

5. The gas temperature inside the boiler determines the installation position of the denitration spray gun

For boilers with urea solution, the denitration spray gun should be installed within the temperature range of 950+50 degrees as far as possible; when ammonia solution is used, the denitration spray gun should be installed at a position of 900+50, and the installation position must avoid the flame. The burning time of the waste liquid is generally required to be above 0.5s to ensure a sufficient reaction; the installation position of the denitration spray gun directly determines the denitration efficiency of the SNCR, and the location of the denitration spray gun is the key point of the SNCR system. The installation of the denitration spray gun is slightly inclined downward, and there is a certain safe distance when it reaches into the furnace;

CFD flow field simulation to determine the injection point;

Install a temperature sensor to test the temperature distribution in the furnace and determine the spray position.

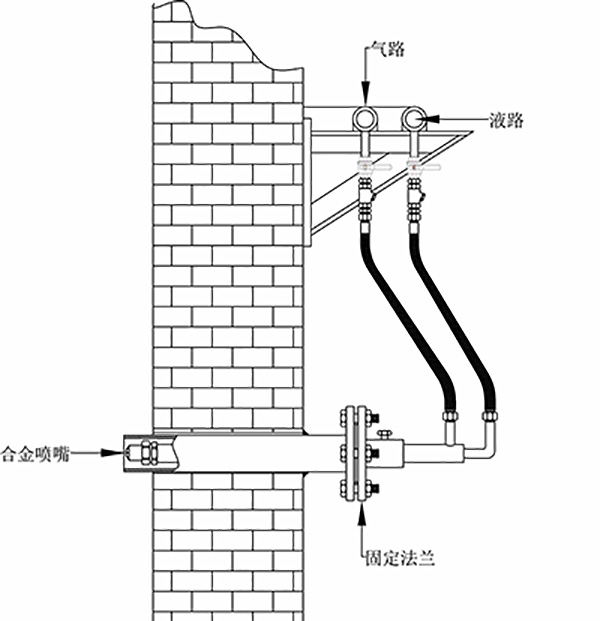

Diagram of the installation position of the denitration spray gun and the physical diagram of the denitration spray gun;

Installation drawing of spray gun

Hotline:021-57675090

Hotline:021-57675090